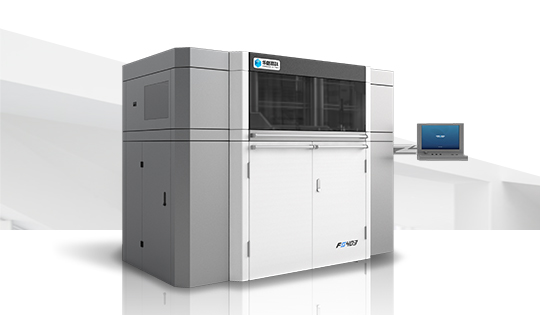

The 403P series is Farsoon’s flagship production polymer system. The 403P Series is offered in multiple configurations ranging from our education system to our high-temperature-capable configuration. Enhanced temperature shielding, laser power and thermal controls enable the 403P series to meet needs from value-based prototyping to full production of Polymer parts.

- Production-ready Open Platform System

- Industrial-scale build envelope up to 400 x 400 x 540 mm

- Powerful 100-watt CO2 laser enable high productivity

Efficiency

Combining high-precision dynamic focusing capability, scan speed of up to 15.2 m/s, with a high efficiency roller system and convenient removable powder cartridge system, the 403P offers increased productivity, manufacturing turn-over rates and lower price per part.

Accuracy

The 403P series' powerful eight-zone heater & intelligent thermal control systems allow for best-in-class temperature regulation enabling less deformation and increased accuracy in final parts.

High-temperature

The 403P series is offered in a high-temperature-capable configuration up to 220℃. Enhanced temperature shielding, laser power and thermal controls enable the HT403P to process high-performance materials, such as PA6, for highly functional, direct end-use applications.

Open Platform

Farsoon is the first laser sintering system producer that allows for complete freedom of operation of its machines. This means that machine parameters and powder choice are unlocked for the user allowing for previously-impossible levels of freedom and flexibility when it comes to PLS production.

- Feed Cartridge: Farsoon's 403P series are designed with exchangeable build and feed cartridges. Once the 403P system completes a build this design allows for the quick swap out of the build and feed cartridges to dramatically reduce machine down time. This robust and flexible operation enables faster production turn-around times to maximize throughput.

- Build Cartridge: The exchangeable 403P series Build Cartridge can be paired with Farsoon's External Cooling Station which enables controlled and inert gas protected cool down outside of the 403P machine. This controlled cool down process helps ensure dimensional accuracy and mechanical performance for the finished parts.

- Breakout Station: The Farsoon FS04-PPS Breakout Station offers efficient powder removal and management while ensuring a clean work environment for the users. The fully enclosed operational chamber with integrated gloves eliminates direct contact with the powder. The Breakout Station includes a built-in sieving screen and powder collection container as well as an external connector for a vacuum to streamline powder handling workflow.

- External Cooling Station: The Farsoon 403P Series External Cooling Station offers efficient cooling and maximizes production yield at the same time. It is designated for cooling the build cylinder part cake right. Once printing job completion for continuous workflow, removing the need for long cool down time inside the main system.

- External Cooling Box: The Farsoon 403P Series External Cooling Station offers efficient cooling and maximizes production yield at the same time. It is designated for cooling the build cylinder part cake right. Once printing job completion for continuous workflow, removing the need for long cool down time inside the main system.

- Powder Management System (PMS): Integrated with multiple powder handling process including used powder recycle & storage, new powder supply, high-speed mixing, and powder sieving, the robust Powder Management System (PMS) enables a streamlined, fully-enclosed material workflow with improved throughput, lower powder refreshment rate and reduced cost per part.

- Powder Delivery Unit (PDU): The PMS system can also be paired with a mobile Powder Delivery Unit (PDU) which transports the prepared powder directly to the printers. Once there the PDU's integrated pump transfers the powder into the printer's powder feed cartridge.

FARSOON 403P Series Technical Specifications

| Technical Data | HT403P |

| External Dimensions (L×W×H) | 2540×1320×2220 mm (100.0×52.0×87.4 in) |

| Build Cylinder Size1(L×W×H) | 400×400×450 mm ( 15.7×15.7×17.7 in ) or 400×400×540 mm ( 15.7×15.7×21.3 in ) |

| Net Weight | Approx. 3100 KG ( 6834.3 lb ) |

| Laser Type | CO2 Laser, 1×100W |

| Scanner | High-precision three-axis digital galvo system |

| Scanning Speed | Max. 15.2 m/s ( 49.9 ft/s ) |

| Max. Chamber Temperature | 220°C ( 428 ℉ ) |

| Technical Data | SS403P |

| External Dimensions (L×W×H) | 2540×1320×2220 mm (100.0×52.0×87.4 in) |

| Build Cylinder Size1(L×W×H) | 400×400×450 mm ( 15.7×15.7×17.7 in ) or 400×400×540 mm ( 15.7×15.7×21.3 in ) |

| Net Weight | Approx. 3100 KG ( 6834.3 lb ) |

| Laser Type | CO2 Laser, 1×100W |

| Scanner | High-precision three-axis digital galvo system |

| Scanning Speed | Max. 15.2 m/s ( 49.9 ft/s ) |

| Max. Chamber Temperature | 190°C ( 374 ℉ ) |

| Technical Data | HS403P |

| External Dimensions (L×W×H) | 2540×1320×2220 mm (100.0×52.0×87.4 in) |

| Build Cylinder Size1(L×W×H) | 400×400×450 mm ( 15.7×15.7×17.7 in ) or 400×400×540 mm ( 15.7×15.7×21.3 in ) |

| Net Weight | Approx. 3100 KG ( 6834.3 lb ) |

| Laser Type | CO2 Laser, 1×55W |

| Scanner | High-precision three-axis galvo system |

| Scanning Speed | Max. 10 m/s ( 32.8 ft/s ) |

| Max. Chamber Temperature | 190°C ( 374 ℉ ) |